Crafts people from the second largest employment sector in India, second only to agriculture. There are around 23 million crafts people in our country today. Even many agricultural and pastoral communities depend on their traditional craft skills as a secondary source of income in times of drought, lean harvests, floods or famine. In today’s world life for craft people remain precarious. Building a future for Indian crafts demands a coherence of heritage and economics. Official support schemes often elude those for whom they are intended, their future now clouded in the uncertainties of a new policy environment. Many traditional raw materials are disappearing under environmental pressure or diverted to competition from large-scale industry. As economic policies take an U-turn and state benevolence withdraws, survival will depend on and ability to compete on the customer’s terms. This has been a capacity completely neglected over fifty years of official direction to Indian crafts, despite Gandhiji’s reminder so long ago.

The handicraft sector is an industry that requires minimum of expenditure, infrastructure or training to set up. It uses existing skills and locally available materials. Inputs required can easily be provided and these are more in terms of product adaptation than expensive investment in energy, machinery or technology. The craft sector contains many paradoxes. Artisanal contribution to the economy and the export market increases every year and more and more crafts people are being created- especially women – as a solution to rural and slum unemployment. At the same time mass produced goods are steadily replacing utility items of daily use made by crafts people, destroying the livelihood of many, without the concomitant capacity to absorb them into industry.

The current much used terms ‘exclusive’ and ‘ethnic’ are singularly limiting and inappropriate when marketing skills and products are with a potential producer base of 23 million. The urban consumer, in spite of a growing awareness of craft, does not have access to many of the products that he would like to buy. One major problem faced by crafts people is that they are bound in their own struggle for survival to money-lenders, traders or middlemen for credit and raw materials and they are obliged to sell their products to them at a minimal price. Despite these adverse conditions, the traditional professional craftsperson has a unique earning power that can be adapted to many usages and markets.

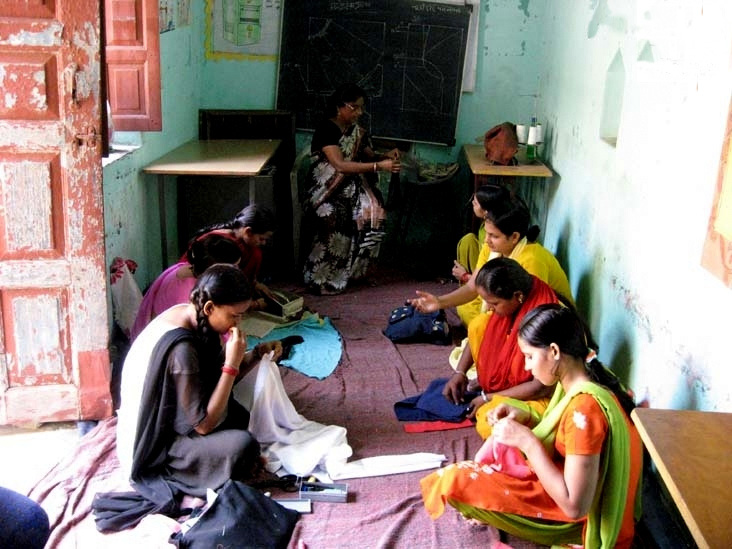

Clothing is one of the basic needs of human being people one becoming fashion conscious. With change in fashion & style, the stitching of garment also changes. Hence keeping in view the market demand and change fashion technology, courses on cutting, tailoring & dress making have been suitably designed in the structure of non formal education. The beneficiaries are new literates and people with low education levels. Besides in Indian tradition girls/women are expected to know tailoring to full fill the basic stitching requirement at home. Stitching of garments at home is a money saving device for lower middle income group. Besides tailoring can be a vocation for self employment.

Tailoring is a conventional and easy way to earn a livelihood for the women in village areas, those who are educated or uneducated and irrespective of caste creed and religion. There is still a better scope for tailoring in the village sector. It was decided to give training to the women on tailoring and embroidery. The women beneficiaries should be married or unmarried, should have completed their minimum standard of education and those who are eager to learn new techniques and methods of today’s life style. The women from all the target villages are been identified and they will be given training in Tailoring and embroidery. 20 women were selected for each batch and they have been trained under this course for a minimum of two months. Only one woman from each village has been selected for the training, and the second one from that village will be selected for the next training. Thus all the women from all the villages are been selected and they will be given training in the prescribed time. Two women instructors have been appointed, one for teaching cutting and tailoring and the other for embroidery.

| Unit | Contents | Theory | Practical |

|---|---|---|---|

| 01. | Introduction to Sewing Machine |

- Machine Operation

- Different parts of Machine and their functions. - Safety precautions - Proper maintenance and oiling |

- Operating machine

- Removing parts and practice in refixing - Adjusting the parts for proper functioning - Practice in cleaning and oiling |

| 02. | Tools and Equipments used in tailoring | Description of various tools

used in tailoring

- Drafting tools: - Cutting Tools: - Stitching tools: |

Practice in using

- Different Scissors - Shaper, L Scale, Art Curve, Tracing wheel - Thimble etc. |

| 03. | Trade Terminology | - Specific terms used in drafting, cutting & stitching | - Practice in using proper Terms. |

| 04. | Measurement Taking | - Use of tape for

measurement

- Proper / correct measurement taking, Precautions - Use of L scale for measurement - Sequence of measurement |

- Practice in using tape

- Taking measurement - Sequencing of Measurement. - Use of L scale |

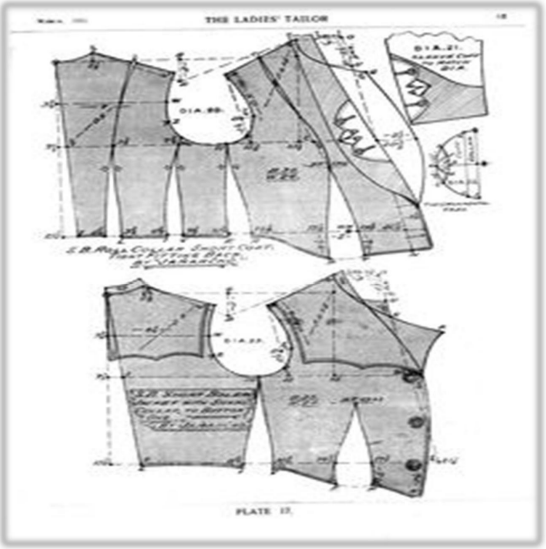

| 05. | Drafting / Pattern Making | - Preparing pattern cuttingdraft - Method of preparingpattern making - Need for drafting and |

- Simple drafting

- Pattern making - Paper pattern cutting |

| 06. | Basic Stitching | - Hand stitches

- Machine stitches - Decorative stitche |

- Preparation of sample pieces of stitches |

| 07. | Construction Skills | - Knowledge about: - Seams, Drafts, Tucks, Pleats, Buttons Hole, Buttons Hooks and snage, Eye, Titch buttons | - Preparation of sample pieces using all construction skills. |

| 08. | Selection of Cloth | - Selection of right type of fabric for a particular garment | - Identification of different types of fabric |

| 09. | Estimation of Cloth | - How to estimate cloth for garments | - Estimation by giving various measurements |

| 10. | Colour concept | Colour combination for buttons, thread & cloth | - Practicals in selection of colour combination (contrast & harmony) |

| 11. | Simple Cutting and Stitching |

- How to mark the

measurements on cloth

before cutting

- Leaving margin for inlays and turnings - Skills in Stitching |

- Marking with different

measurement

- Cutting the cloth as per marking, leaving margin for inlays and turnings. - Practice in stitching on paper for straight zigzig, round etc. - Stitching of - Handkerchief / Bib / Pillow cover / Bags / Underwear / Quilting |

| Unit | Contents | Theory | Practical |

|---|---|---|---|

| 01. | Construction skills | - Use of velcrow & Elastic | - Fixing velcrow &

- Elastic insetion |

| 02. | Practical work on Tailoring Skills | Drafting, paper pattern making, cutting, stitching and finishing of following garments: Children Garments EITHER Ladies Garments Or Boys / Gants Garments | Stitching of different baby garments Stitching of different ladies garments Stitching of different gents garments |

| Unit | Contents | Theory | Practical |

|---|---|---|---|

| 01. | Construction skills | - Type of facing,

binding

- Zip application - Elastic insertion - Design darts, Yokes & midrift - Waist band application |

Practice in construction skills |

| 02. | Tailoring skills | - Notch collar-Roll collar | Drafting, paper pattern making, cutting and stitching of garments: EITHER Ladies garments OR Gants garments |

| 03. | Other skills | - Tailor marks

- Fittings & alterations - New garments from old fabric / garments |

|

| 04. | Pressing & Packing Skills (Folding) | Precautions to be taken while pressing and folding | - Pressing of:

- Cotton garments - Terene garments - Silk garments - Packing of various garments (folding). |

| Unit | Contents | Theory | Practical |

|---|---|---|---|

| 01. | Designing | Dress Designing - Principles & concept | |

| 02. | Pattern Making | - Creative pattern

making

s- Types of pattern & Bodice block |

- Sample making |

| 03. | Bodice Blocks | Measurement taking

- Drafting and pattern making of following blocks A. Children: - Basic Bodice Block - Sleeve, Skirt Block B. Ladies: - Basic Bodice Block - Sleeve / Trouser Block |

|

| 04. | Manipulation and adjustment | What is manipulation / adjustment | Practice of:

- Dart / Sleeve / Collar manipulation - Adjustment for different figures - Stooping/ flat bust / full bust - Manipulation & making various creative patterns through the blocks in the following: - Children/Ladies/Gants garments/Sleeves/Collars / Pockets/ Cuff/ Jackets |

| 05. | Fittings | Problems of fitting and correction | Practice in correcting patterns |

| 06. | Colour Concept | - Colour concept and harmony in designing | - Preparation of samples. |

Embroidery is a beautiful thread work on a variety of fabrics, which make the fabric more attractive. It is an important and useful method of creating design on different fabrics it lend three dimensional effects and can be done on fabric, garment & pattern pieces and stitched garments. Due to wide diversity in our country, we find variety in embroidery stitches, colours and motifs. The craftsmanship from every state has its own Excellency, attracting people from all parts of the world. Each state in the country is unique in it and is reflected in the embroideries of that particular state. Due to the invasion of modern technological advancements traditional hand embroidery is gradually fading out therefore there is need to revive the tradition and inculcate the art of appreciation in students. Moreover to train the students to popularize the traditional embroideries into industrial crafts in order to save he reminiscent beauty of the past and everlasting art.s

For women in the area to learn embroidery sewing is not any centre which women are not getting the opportunity to learn embroidery sewing.

Embroidery sewing them to the knowledge of women must be self-sufficient in order to pass it to our own lives can fulfil their life.

Pathfinder embroidery can be made by testing the women self-reliant so that he could fulfil his life.

Weightage: - Theory – 40%

Practical – 50%

Internal - 10%

Scheme of Examination: - Theory – 2 hrs. Practical – 4 hrs.

Passing Criteria: - Theory 40%

Practical 50%

Aggregate 50%

Traditionally, black work

Traditionally, black work was used on clothing. The focus of black work is generally the variety of filling patterns used within the elements of the design. Looking at black work from the 16thcentury, a design could include vines, leaves, and flowers stitched with a heavy outline, but the inside of the leaves and flowers would be intricately filled with lacy, usually geometric, patterns.

In earlier centuries, black work was worked normally on white or light linen with black thread, but today, it is often seen on dyed fabrics and worked in a variety of colours. Variegated silks are a popular choice for black work today.

Black work commonly employs a variety of filling patterns worked in Holbein stitch, which looks like backstitch, but is actually reverse running stitch. The design is worked in one direction in running stitch, leaving a stitch space between each stitch. Then, the embroiderer works the design in the opposite direction, filling in the empty spaces with another running stitch.

Modern black work is popularly used to create geometric designs, but can also be used to stitch beautiful “picture” embroidery. Various levels of shading can be achieved in black work by varying the filling stitches and patterns and the weight of the thread. Modern Black work is often effectively combined with counted cross stitch and surface techniques to good effect.

Canvas work

Canvas work, known in the US as needlepoint, is worked on canvas, rather than fabric. Canvas work is done on two types of canvas, either mono canvas or Penelope canvas, and all types of threads can be used, including wool, silk, cotton, blends, and synthetic threads with interesting textures. As for stitches, there are myriad needlepoint stitches to choose from, though the most common stitch for filled and shaded pictures in needlepoint is tent stitch (a half cross stitch). Needlepoint is a counted technique when worked on a blank canvas from a gridded pattern. It can also be done on painted canvases, with the stitcher covering the painted areas with corresponding colours of thread. Canvas work makes excellent household upholstery (for footstool covers, chair seats, etc.) as well as decorative household items such as accent pillows. It can also be framed, used as book covers, made into purses and bags, formed into dimensional sculptors, made into doorstops – practically anything can be done with it! Chickenscratch Chicken scratch, worked on gingham, is generally considered a more “rustic” embroidery technique. The squares of the gingham provide the grid upon which chicken scratch is worked, with the stitches producing a lacy pattern on the gingham.

Chicken scratch is a simple technique; it employs only a few stitches, and therefore, it’s great for children. But don’t be fooled! By combining stitches and thread weights and varying stitch types, intricate patterns can be produced with chicken scratch, and, when stitched on finer the gingham, the finer the results. Normally, cotton threads are used for chicken scratch. The technique is often seen on household kitchen items, such as aprons, towels, and the like, as well as other household goods, like decorative pillows and curtains.

Counted cross stitch

Counted cross stitch is an embroidery technique that uses cross stitches to create the picture being stitched. It is worked on even-weave fabric. The even weave of the fabric corresponds to the gridded pattern that determines the placement of the stitches.

In the US, counted cross stitch has enjoyed unparalleled popularity when compared to most other types of needlework. Most needlework shops in this country cater primarily to count cross stitch and secondarily to needlepoint. There are few needlework shop’s the inventories of which do not include a heavy focus on counted cross stitch.

In recent years, a resurgence of interest in historical samplers has given rise to the popularity of beautiful designs that are reminiscent of historic needlework. European styles of cross stitch (and other needlework adapted to cross stitch) have also become very popular. In samplers, counted cross stitch is often combined with other stitches and with other types of needlework, such as drawn thread work. These combinations have been beneficial to both the look of cross stitch (which has become more intricate) and the skill of the needle worker.

Crazy quilting

Crazy quilting can look to the Victorian era for its popular beginnings, and today, crazy quilting is certainly equally or more popular than it was 150 years ago. Crazy quilting sprang from a cross between necessity and the desire for beautifully embellished items of necessity. Irregular scraps of fabric were salvaged and re-made into quilts that were used for warmth, and to beautify the irregularity of the quilts made from scraps, the seams and squares were embellished according to the stitcher’s fancy.

Crazy quilting is certainly a free form of embroidery. Unlike most surface embroidery, this style of needlework is not dependent on any particular type of fabric, nor on any specific type of thread, nor any specific rules, really. All fabrics are game to the crazy quilter, and all threads and items of embellishment are part of the crazy quilter’s arsenal.

The ground for the needlework in crazy quilting is usually a patched quilt square made out of irregular shapes and sizes of fabric. The threads are many and varied – from cotton floss to pearl cottons, to silks, to wool, to … you name it! Ribbon embroidery is often employed. The stitches used in crazy quilting are really any stitches, in any combination that the stitcher wants to tackle. Bits of lace and ribbon, buttons, beads, and charms find their way into crazy quilt items as well.

Recently, crazy quilting has become a more precise art in the development of crazy quilted landscapes and images. For example, selecting fabrics that match the colour of sky, earth, water, green fields, etc., the crazy quilter may piece together an image reminiscent of an Impressionist landscape. Then, using needle and thread, the crazy quilter adds dimension to the pieced fabric landscape by stitching in bark and leaves on trees, flower beds, texture in the sky, in the water, in the grass – all of which brings the landscape to life. The finished effect can be quite stunning.

Drawn thread embroidery

Drawn thread embroidery is a technique worked normally on linen, with horizontal or vertical threads in the linen removed from the fabric and decorative stitches worked over the remaining threads. Drawn thread work often creates a lacy effect, although it can also be a very rustic-looking needlework technique, depending on the type of linen and thread used.

Drawn thread embroidery is often used in combination with other surface embroidery, especially white work, but also counted cross stitch.

Drawn thread work is particularly suited to household linens and church linens. It requires an even-weave (or close to it) ground fabric.

Needle lace

Needle lace is not always an embroidery technique, although embroidery stitches are used on most types of needle lace. Lace can be made a number of ways – with bobbins, tapes, crochet hooks, and with regular needles. Needle lace is lace made with needle and thread, normally on a fabric ground and often with parts of the fabric cut away. Some types of needle lace are not worked on fabric, but rather on paper or tissue, and once removed from the tissue, the resulting piece of needle lace is then attached to the fabric. Some types of needle lace are made on a net ground (either square netting like filet netting, or tulle). And some types of needle lace are actually a combination of bobbin lace with stitching on it.

Needlepainting

Needlepainting goes by several other names, including thread painting, long and short stitch shading, and silk shading. Needlepainting is a technique used for filling areas realistically and for “painting” images with needle and thread.

The stitch commonly used in needlepainting is long and short stitch, although other stitches are sometimes employed to achieve a realistic look to the image.

Needlepainting can achieve very fine, artistic detail. The technique is sometimes combined with goldwork to good effect.

Silk ribbon

Silk ribbon embroidery is embroidery worked with silk ribbon. This luxurious needlework can range from fine, detailed work to bold, vivid, and abundant.

The motifs featured in silk ribbon embroidery are almost always floral.

Silk ribbon embroidery (commonly called SRE) can be used to embellish lots of things: household items like decorative pillows, book covers, clothing, and even greeting cards.

About the Embroidery

Embroidery is the method used for decorating fabrics with a needle and a thread. Embroidery styles and techniques vary greatly but in this tutorial, DMC will be featuring free style or "surface embroidery." This decorative stitching technique, with its varied stitches, is worked independently from the fabric's weave allowing you to embroider any design, realistic or abstract, onto any fabric you choose. Surface Embroidery offers you the greatest versatility to create beautiful designs using DMC's colourful threads and specialty fibbers.

Embroidery Styles

The versatility of embroidery lends itself to numerous styles, and each has its loyal supporters. These are just a few types to consider.

Crewel

This form uses wool thread and a variety of stitch types, including split, satin, and chain stitches. Given the thickness of the thread, designs are usually somewhat large and bold. It uses firm fabrics, such as linen, cotton, jute, and velvet.

Cross Stitch

Counted cross stitch involves precise placement of x-shaped stitches on fabric that has evenly spaced threads and stitch holes. Stamped cross stitch involves stitching over a pre-printed picture. Stiff Aida fabric is common, but linen, perforated paper, plastic, and vinyl are also used. Cotton floss is the most common thread material.

Needlepoint

This form of counted stitching uses canvas with evenly placed stitch holes. Thread may be silk, cotton, wool, or wool blends. Canvases are measured by thread counts, similar to cross stitch; a few types include Mono, Penelope, and plastic canvases. Needlepoint may use only a couple of stitch types or a variety of them.

Needle Painting

This extraordinary form of embroidery uses very closely placed, long and short stitches to create a detailed and intricate picture. Stitches are placed in different directions to simulate the brush strokes of a painting, and each row of stitches splits the previous row to help blend the work. This form is also called thread painting or silk shading, and it uses many colors to create a realistic picture.

Blackwork, Bluework, Redwork, and Whitework

11These embroidery forms use a single, named colour of thread on white or natural-colour fabric; white work uses only white fabric. Stitching methods include cross stitch and crewel, but designs often consist of outlines without filled areas. White work can be more elaborate and uses a variety of techniques, including hard anger.

Hardanger

Hard anger may use cream thread on cream fabric, but it specifically uses the same color of thread and fabric. Designs are usually geometric in form, using specific shapes. It employs various stitch types, including satin stitch and French knots.

Stitch Types

The creativity and art of embroidery depend heavily on the stitches used. Each type creates a unique appearance, and as with every other element, there are multitudes of types and variations. This is a brief overview of a few common stitches.

Straight Stitch

In this very basic stitch, the needle comes up through the fabric and down again at a forward point. Straight stitches are often used in a line or in adjacent placements.

Chain Stitch

One of the oldest decorative stitches in use, the chain stitch is also known as the Tambour stitch. The needle comes up through the fabric, drawing the thread through,and then moves back down through the same hole, leaving a small loop of thread above the fabric. The needle then comes back up in a forward position that catches the loop and anchors it with the next stitch.

Split Stitch

This stitch is also known as a Kensington stitch, and it's frequently used to outline other stitched areas or as fill-in shading. It requires thread that can be split easily, such as crewel or tapestry yarn and embroidery floss. The needle moves down behind the last stitch and then up through the middle of the thread in that previous stitch.

Buttonhole Stitch

Buttonhole stitches are also known as blanket stitches. They are the foundation for many other stitch types and can also prevent fabric edges from raveling. The needle comes up through the fabric, and the thread is laid horizontally to the right. Above the horizontal thread at a right angle, the needle moves down through the fabric and then up again near the horizontal line, anchoring the thread segment with the next stitch; buttonhole stitches resemble a backward L.

Satin Stitch

Sometimes called Damask stitch, this embroidery technique places several straight stitches very close to each other over an area of fabric, which creates a satin appearance. Careful alignment of satin stitch edges keeps them smooth and even.

Backstitch

Backstitches are often used in outlining. The needle comes up at a point forward from the last stitch, leaving a blank space, and then moves backward to the point just in front of the previous stitch to cover the space.

Cross Stitch

For these x-shaped stitches, the needle comes up through a lower-left stitch hole and moves diagonally to the upper-right stitch hole and through it. The needle then comes up through the hole directly beneath, which is the lower-right stitch hole, and completes the x-shape by moving down through the upper-left position. Typically, the first halves of the x-shapes in a row of stitches are all stitched first; the top halves are completed when moving back across the row.

Knotted Stitches

These stitches leave a knot above the fabric as a decorative accent, and there may be groups of knots to create a particular effect for flowers and other designs. Knotted stitches generally involve bringing the needle up through the fabric, wrapping the thread around the needle one or more times, and then moving the needle back down through the fabric very close to the initial point, perhaps only a thread away.

Embroidery Materials

Basic embroidery materials include cloth, needles, thread, and patterns. A few items related to patterns are frequently required as well, and other accessories come in very handy.

Cloth

An extensive range of cloth and other items can serve as embroidery canvas. Silk, cotton, linen, leather, felt, hats, shirts, bags, jeans, and towels are just a few examples. The choice is largely up to the stitcher's imagination.

Needles

Hand embroidery needles vary by the type of stitching, the stitching material, and the cloth on which the embroidery will be performed. The needle length, thickness, eye size, and even sharpness are specific to the embroidery style. Yarn work requires a thicker needle and a larger eye than stitching done with silk thread. Likewise, fine silk fabrics need a thin, sharp needle while counted embroidery styles typically use a blunt needle.

Thread

Embroidery thread encompasses a variety of materials. Embroidery floss or thread is often made from cotton. Other materials include silk, rayon, satin, and blended threads. Metallic threads are common as are ribbons and wool or other embroidery yarns. Embroidery also uses braids, beads, and other accessories to enhance designs.

Patterns

Embroidery patterns are limited only by the imagination. Traditional designs, landscapes, portraits, lettering, numbering, animals, flowers, and nature images are only the beginning. Fabric is sometimes preprinted with a pattern; otherwise, the pattern must be transferred to the fabric. Iron-on patterns, embroidery stencils,, and tracing are common transfer methods. Those who can draw freehand have that option as well.

Use of zari embroidery was an indispensable part of the dress work by the kings and queens. The history of this industry dates back to past several centuries. The embellishing handicraft work of zari embaroidery is being done on the dress materials like saree (80%), salwar/kameez, ghagra, churidar, Punjabi, curtains scarf etc. Among the above products zari embroidered saree is the main product. Zari embroidered dress materials have very good potential in the domestic market as well as in the export market.

Surat is the home of Zari Industry in India. It make embroidery materials for machine and hand embroidery such as zari thread/kesab, Nakshi, Salmo, Sadi, kangri and badle, woven trimmings, flat trimmings, metallic trimmings, fringes, metallic fringes in different colours and different widths. Sequin collar and motifs in elegant colours and designs are also made. These enhance the beauty of garments. There are three types of zari. Real zari is made of silver and electro plated with gold. Zari thread made from this precious metal is used for sarees, embroidered apparel, etc. Imitation zari is made from copper. A third variety of zari is called plastic zari which is made from metallic yarn. At present total production of zari raw material in India is valued about Rs. 500 crore. About 55% of these zari raw materials is catered by Surat. Except Surat Zari raw materials are produced at Barielly, Varanasi, Agra, Jaipur and Barmer.

Benefits of Embroidery

Market Scope & Demand

Tendency to wear Indian Zari embroidery products among Indian and Western women is increasing rapidly. Strong domestic market as well as growing export market is there. Besides there is a good scope of product diversification according to fashion dynamics.

Raw materials

Siphon Cloth, Ribbon Orgenja cloth, Glass Beads, Jorjet cloth, Resham, square tiki, Nimzari, zari thread etc. – all are available in the local market.

1Manufacturing Process and Source of Technology

Handicraft of Zari Embroidery is being done on the dress materials like Saree, Salwar, Churidar, etc. First, the cloth is tied on wooden Dhadda fitted with wooden stand. Required design is stenciled with the help of stencil paper on the cloth. Embroidery work is being done according to the design by Zari thread, stone, beads, etc. This is a traditional artisan work.

Sangrur District Overview

An official Census 2011 detail of Sangrur, a district of Punjab has been released by Directorate of Census Operations in Punjab. Enumeration of key persons was also done by census officials in Sangrur District of Punjab.

In 2011, Sangrur had population of 1,655,169 of which male and female were 878,029 and 777,140 respectively. In 2001 census, Sangrur had a population of 1,473,242 of which males were 787,795 and remaining 685,447 were females. Sangrur District population constituted 5.97 percent of total Maharashtra population. In 2001 census, this figure for Sangrur District was at 6.05 percent of Maharashtra population.

There was change of 12.35 percent in the population compared to population as per 2001. In the previous census of India 2001, Sangrur District recorded increase of 18.36 percent to its population compared to 1991.

| Description | 2011 | 2001 |

|---|---|---|

| Actual Population | 1,655,169 | 1,473,242 |

| Male | 878,029 | 787,795 |

| Female | 777,140 | 685,447 |

| Population Growth | 12.35% | 18.36% |

| Area Sq. Km | 3,625 | 3,625 |

| Density/km2 | 475 | 400 |

| Proportion to Punjab Population | 5.97% | 6.05% |

| Sex Ratio (Per 1000) | 885 | 870 |

| Child Sex Ratio (0-6 Age) | 840 | 784 |

| Average Literacy | 67.99 | 59.90 |

| Male Literacy | 73.18 | 66.00 |

| Female Literacy | 62.17 | 53.00 |

| Total Child Population (0-6 Age) | 181,334 | 0 |

| Male Population (0-6 Age) | 98,547 | 0 |

| Female Population (0-6 Age) | 82,787 | 0 |

| Literates | 1,002,077 | 0 |

| Male Literates | 570,413 | 0 |

| Female Literates | 431,664 | 0 |

| Child Proportion (0-6 Age) | 10.96% | 0.00% |

| Boys Proportion (0-6 Age) | 11.22% | 0.00% |

| Girls Proportion (0-6 Age) | 10.65% | 0.00% |

Sangrur District Density 2011

The initial provisional data released by census India 2011, shows that density of Sangrur district for 2011 is 457 people per sq. km. In 2001, Sangrur district density was at 400 people per sq. km. Sangrur district administers 3,625 square kilometers of areas.

Sangrur Literacy Rate 2011

Average literacy rate of Sangrur in 2011 were 67.99 compared to 59.90 of 2001. If things are looked out at gender wise, male and female literacy were 73.18 and 62.17 respectively. For 2001 census, same figures stood at 66.00 and 53.00 in Sangrur District. Total literate in Sangrur District were 1,002,077 of which male and female were 570,413 and 431,664 respectively. In 2001, Sangrur District had 0 in its district.

Sangrur Sex Ratio 2011

With regards to Sex Ratio in Sangrur, it stood at 885 per 1000 male compared to 2001 census figure of 870. The average national sex ratio in India is 940 as per latest reports of Census 2011 Directorate. In 2011 census, child sex ratio is 840 girls per 1000 boys compared to figure of 784 girls per 1000 boys of 2001 census data.

Sangrur Houseless Census

In 2011, total 600 families live on footpath or without any roof cover in Sangrur district of Punjab. Total Population of all who lived without roof at the time of Census 2011 numbers to 3,150. This approx 0.19% of total population of Sangrur district.

Sangrur District Urban/Rural 2011

Out of the total Sangrur population for 2011 census, 31.17 percent lives in urban regions of district. In total 515,965 people lives in urban areas of which males are 273,376 and females are 242,589. Sex Ratio in urban region of Sangrur district is 887 as per 2011 census data. Similarly child sex ratio in Sangrur district was 869 in 2011 census. Child population (0-6) in urban region was 59,010 of which males and females were 31,580 and 27,430. This child population figure of Sangrur district is 11.55 % of total urban population. Average literacy rate in Sangrur district as per census 2011 is 75.11 % of which males and females are 79.75 % and 69.90 % literates respectively. In actual number 343,220 people are literate in urban region of which males and females are 192,826 and 150,394 respectively.

As per 2011 census, 68.83 % population of Sangrur districts lives in rural areas of villages. The total Sangrur district population living in rural areas is 1,139,204 of which males and females are 604,653 and 534,551 respectively. In rural areas of Sangrur district, sex ratio is 884 females per 1000 males. If child sex ratio data of Sangrur district is considered, figure is 827 girls per 1000 boys. Child population in the age 0-6 is 122,324 in rural areas of which males were 66,967 and females were 55,357. The child population comprises 11.08 % of total rural population of Sangrur district. Literacy rate in rural areas of Sangrur district is 64.79 % as per census data 2011. Gender wise, male and female literacy stood at 70.22 and 58.70 percent respectively. In total, 658,857 people were literate of which males and females were 377,587 and 281,270 respectively.

Almighty International society is registered in India under the Societies Registration Act of 1860 with its registered office at Punjab. Registration number DIC/DRA/6359 on the 17th of May 2011.

Statutory Documents

©2026, All Rights Reserved | Design by Viver Technologies